warprints

Rifleman

Hi.

I'm new here, I'd like to show you some of my work.

I've only done 1/16 scale for a few years but always liked the large models.

Bigger is better.

So I decided to try something bigger as well.

I did Hetzer in 1/16 scale first.Since I do all my 3D models in real size (1/1) first and then scale down and possibly take away details so it was no problem to use that base model for 1/6 size and give it a try.

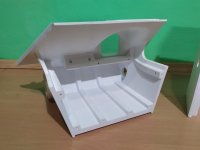

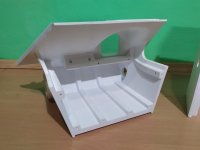

The only downside to this first model was that I used the 1/16th scale part divisions from the original model, which created a major limitation - the basic body parts are very large and require the largest 3D printers to produce them.

I changed this only with the second model, which is divided into parts differently than the 1/16 version and can be made on standard printers.

I always design everything as RC from scratch.

I never spare on materials and the parts are robust and designed in such a way that there is no need to replace, for example, the lower hull with a metal one.

There is no twisting of the hull when driving.

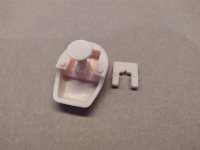

All mechanical parts can be disassembled for servicing or maintenance.

The cannon and machine gun can be uninstalled in a minute for transport in the car.

Hetzer is usually around 14kg (31lgs) without battery.

The propulsion system is always all metal.In 1/6 scale it is not possible to use plastic parts as for example in 1/10 scale.

Hetzer has 550 size engines with metal gearing.

The motor shaft is directly connected to the sprockets.

Some people don't like this solution very much, but I haven't had any bad experiences with it.

The same way those little electric cars for kids are designed and they handle it without any problems.

As I was saying, the parts are massive.

The parts are glued together and at the same time connected by bolts and nuts.

The screws strengthen the joint, but at the same time make it very easy to glue and align the parts correctly.

I'm new here, I'd like to show you some of my work.

I've only done 1/16 scale for a few years but always liked the large models.

Bigger is better.

So I decided to try something bigger as well.

I did Hetzer in 1/16 scale first.Since I do all my 3D models in real size (1/1) first and then scale down and possibly take away details so it was no problem to use that base model for 1/6 size and give it a try.

The only downside to this first model was that I used the 1/16th scale part divisions from the original model, which created a major limitation - the basic body parts are very large and require the largest 3D printers to produce them.

I changed this only with the second model, which is divided into parts differently than the 1/16 version and can be made on standard printers.

I always design everything as RC from scratch.

I never spare on materials and the parts are robust and designed in such a way that there is no need to replace, for example, the lower hull with a metal one.

There is no twisting of the hull when driving.

All mechanical parts can be disassembled for servicing or maintenance.

The cannon and machine gun can be uninstalled in a minute for transport in the car.

Hetzer is usually around 14kg (31lgs) without battery.

The propulsion system is always all metal.In 1/6 scale it is not possible to use plastic parts as for example in 1/10 scale.

Hetzer has 550 size engines with metal gearing.

The motor shaft is directly connected to the sprockets.

Some people don't like this solution very much, but I haven't had any bad experiences with it.

The same way those little electric cars for kids are designed and they handle it without any problems.

As I was saying, the parts are massive.

The parts are glued together and at the same time connected by bolts and nuts.

The screws strengthen the joint, but at the same time make it very easy to glue and align the parts correctly.